Wholesale Metallic Catalytic Manufacturers - Honeycomb ceramic catalytic converter with metallic carrier – Hualian

Wholesale Metallic Catalytic Manufacturers - Honeycomb ceramic catalytic converter with metallic carrier – Hualian Detail:

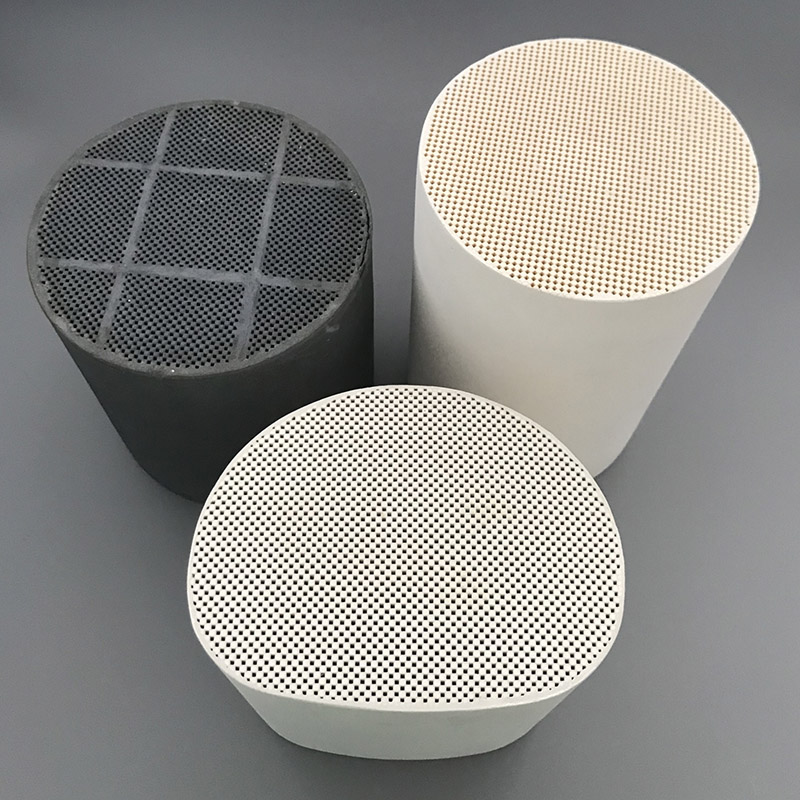

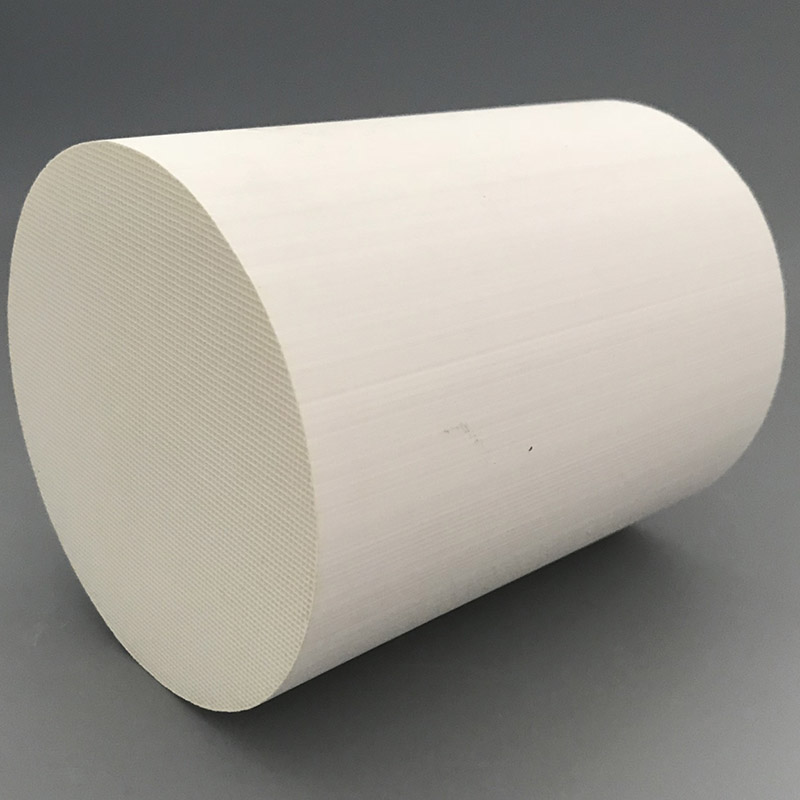

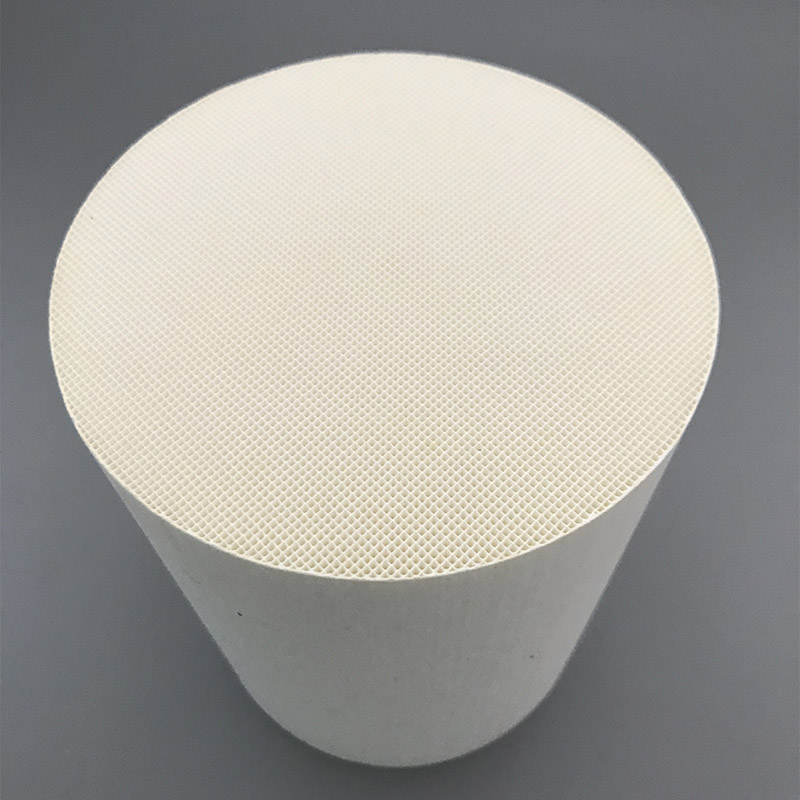

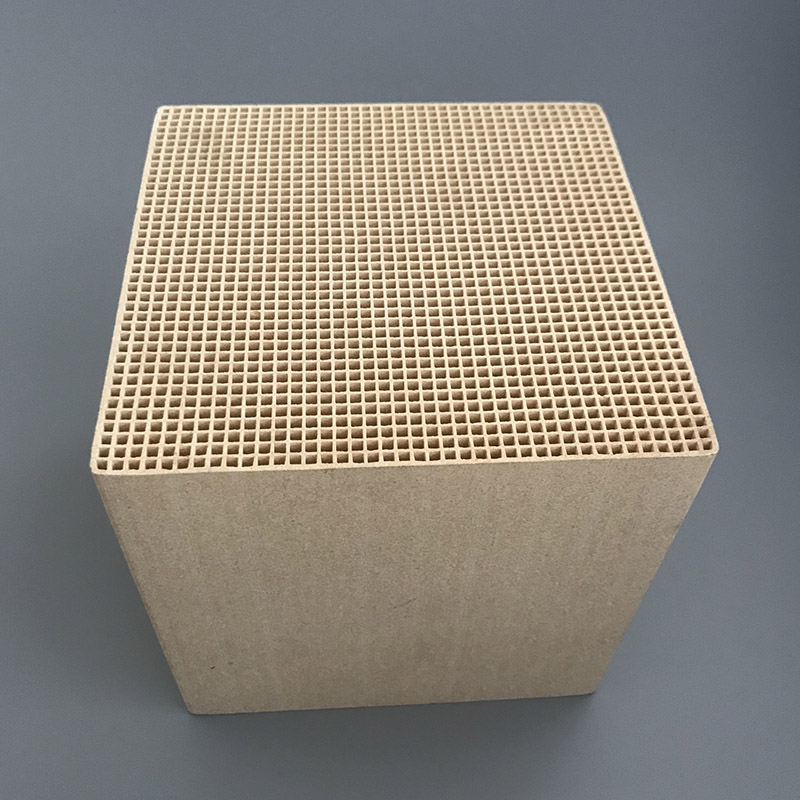

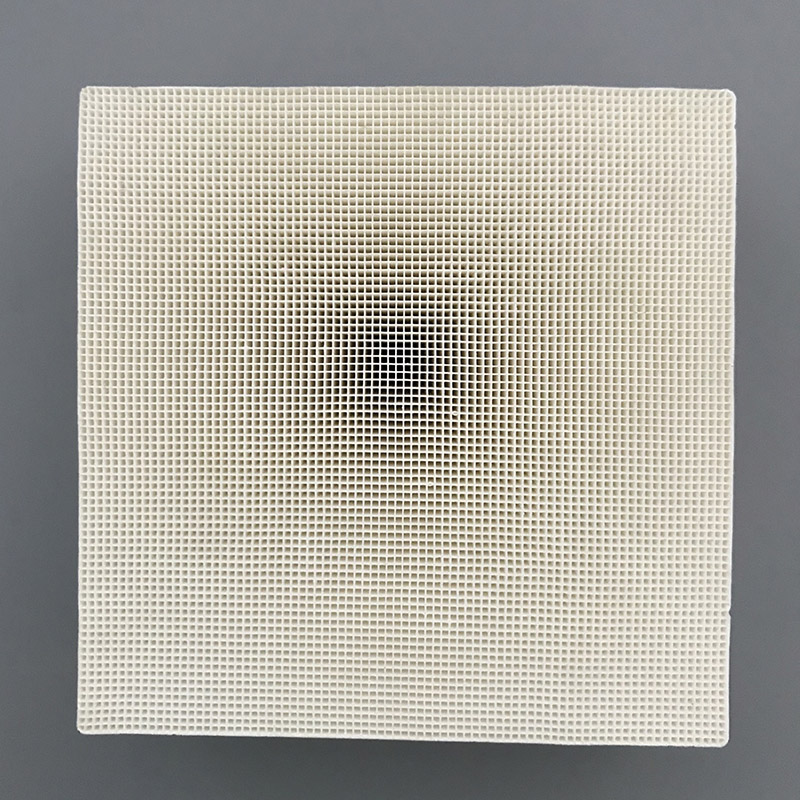

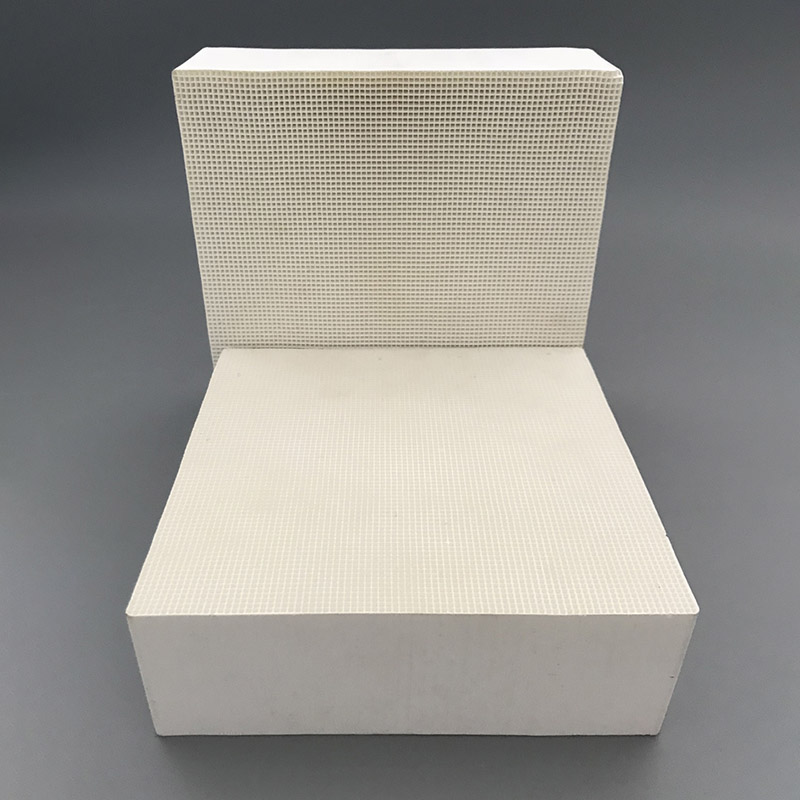

Honeycomb ceramic products have many parallel flow channels, so the pressure loss of gas flow is small, and the flow distribution in the whole component is good. Coupled with the thin-walled network structure of honeycomb ceramics, they have light weight, high specific strength and large specific surface area. They are widely used in heat exchangers, radiators, catalyst carriers, sound insulation materials, etc.

In the field of automobile exhaust purification, honeycomb ceramics play a very important role as catalyst carrier. This is because the catalytic reaction of automobile exhaust can activate harmful components (such as carbon monoxide, hydrocarbons, nitrogen oxides, etc.) in the exhaust and carry out chemical reaction to convert them into harmless carbon dioxide, water and nitrogen. Honeycomb ceramics provide an important place for the adhesion of catalysts. The vehicle catalyst carrier puts forward the following specific requirements for honeycomb ceramics:

Good thermal stability. The exhaust temperature of automobile engine is between 250-950 ℃, but sometimes even more than 950 ℃, which may lead to the phase transformation of the support material at high temperature, affecting the activity and service life of the catalyst, so the requirements for the thermal stability of the catalyst support are high.

High mechanical strength. Engine exhaust has thermal shock, bumpy road surface and cylinder vibration, which all put forward strength requirements for catalyst support.

Large specific surface area. The specific surface area of catalyst support is large, which is conducive to the attachment and dispersion of catalyst active substances, so it can greatly improve the activity of catalyst.

Low heat capacity. When the engine is cold started, the container produces more carbon monoxide and hydrocarbons. If the heat capacity of the carrier is low, the catalyst can reach the working temperature in a short time and play a catalytic role as soon as possible.

Good corrosion resistance. Automobile exhaust contains a lot of corrosive gases.

Small air resistance. The installation of catalyst carrier will produce back pressure on the engine, which must not affect the normal operation of the engine as much as possible. Therefore, it is hoped that the pressure difference generated after the air flow passes through the carrier will be as small as possible.

Low coefficient of thermal expansion. The lower coefficient of thermal expansion is conducive to the catalyst support to withstand the working environment of rapid cooling and rapid heating without cracking.

At present, cordierite honeycomb ceramics are mostly used as vehicle exhaust purification catalyst carrier. Cordierite honeycomb ceramics were first prepared by American Corning company (yes, Corning gorilla glass, which supplies glass backplane for Apple mobile phone) through extrusion molding in the 1960s.

For the extrusion molding of cordierite honeycomb ceramics, there are two process options: raw meal and clinker, and the main difference between the two processes is whether there is a pre synthesis link of cordierite powder. In the clinker process, cordierite powder is synthesized first, and then extruded; In the raw meal process, cordierite is synthesized by extrusion and sintering. Figure 4 shows two production processes of cordierite honeycomb ceramics.

In addition to the different production processes, the raw materials for cordierite honeycomb ceramics come from a wide range of sources, and the major manufacturers are also different. As shown in Figure 5, we can see the diversity of raw material selection.

Due to the high performance requirements of vehicle honeycomb ceramics (many key points listed above), the specifications of raw materials are strict. For example, it is specified that the median particle size of cordierite powder is within 10-50um, the average particle size of talc source is at least 8um, the average median particle size of alumina source is not more than 5um, and the average median particle size of kaolin and calcined kaolin mixture is not more than 6um.

In addition to particle size, in recent years, it has also been found that the morphology of cordierite powder has a great influence on the final product. Because the sheet shape has strong anisotropy during extrusion molding (this was introduced in the previous article on extrusion molding. It is reasonable that we want to avoid anisotropy, but why can’t we use it?). In a U.S. patent named “anisotropiccordierite molonlish”, Lachman i.m. and others make full use of the sliding and overturning of flaky kaolin to make it tend to plane orientation. After firing, the orientation arrangement of cordierite grains in honeycomb structure can be realized. The oriented cordierite has anisotropy in thermal expansion, so it can reach a low thermal expansion coefficient (the final thermal expansion coefficient is only 0.55) × 10-6/℃)。

At present, the core technology for the production of high-end cordierite honeycomb ceramics is still mastered by companies represented by Corning of the United States and NGK of Japan. However, with the continuous expansion of vehicle catalyst carrier market and the continuous growth of domestic research force, domestic substitution for import is becoming a reality.

Finally, it is worth mentioning that recently, Shanghai announced that the “national six” standard will be implemented from July 1 this year. Compared with the national five standards, the national six standards are much stricter as a whole, mainly including:

(1) Carbon monoxide emissions from gasoline vehicles reduced by 50%

(2) The emission limit of total hydrocarbons and non methane total hydrocarbons decreased by 50% (23% from country IV to country V)

(3) The NOx emission limit was tightened by 42% (reduced by 28% from country IV to country V)

With the rapid growth of the domestic automobile market and the further improvement of emission standards, there is a huge market demand for cordierite honeycomb ceramics for exhaust gas purification. It is believed that domestic cordierite honeycomb ceramics for vehicles can have better development in the future.

Product detail pictures:

Related Product Guide:

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of Wholesale Metallic Catalytic Manufacturers - Honeycomb ceramic catalytic converter with metallic carrier – Hualian , The product will supply to all over the world, such as: Moldova , Milan , Philippines , We mainly sell in wholesale, with the most popular and easy ways of making payment, which are paying via Money Gram, Western Union, Bank Transfer and Paypal. For any further talk, just feel free to contact our salesmen, who are really good and knowledgeable about our prodcuts.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.